- About us

- Products

- Services

- Contact

=O=

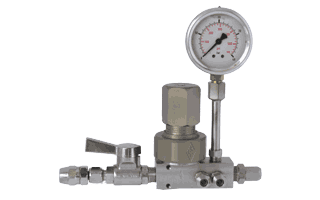

Lacquer Pressure Regulator PRM-2000, mechanic

Prospect Download

1. Introduction to top

The APSON Lacquer Pressure Regulator PRM-2000 is a

mechanically controllable pressure regulator for often changing aggressive media. It keeps the media pressure at the exit constant and independent of the pressure fluctuations of the medium supply system at the entrance

of the regulator, if the input pressure is larger than the preset exit pressure.

The regulator is particularly optimized for good rinsing barness and small solvent consumption. Therefore it is particularly suitable to the employment in automatic systems for the processing of lacquers, solvents, caustic solutions, a.o.

APSON Lacquer Pressure Regulator PRM-2000

2. Features to top

-

Environmental carefully due to short rinsing times.

-

Very good rinsing barness and small solvent consumption.

-

Small pressure losses.

-

Rational maintenance and spareparts holding.

-

Very fast exchange of a defective diaphragm (2 minutes).

-

Simplest handling at assembling, adjustment and maintenance.

-

Small, compact size.

3. Structure and Function to top

The APSON Lacquer Pressure Regulator PRM-2000 consists of a medium pressure space, which is separated from the compression spring space by means of a solvent-resistant diaphragm. The diaphragm is subjected on one side with the pressure of the to be regulated

medium and on the other side with the force of the manually adjustable compression spring.

A thrust piece connected with the diaphragm controls the medium quantity per time unit, flowing through the pressure regulator, via a throttle provided with a ball. The regulation procedure is achieved through the equilibrium of the force between the

compression spring on one hand, and by the resulting strength due to the medium pressure together with the force of the recoil spring in the supply drilling of the throttle on the other hand.

The desired medium pressure at the output of the regulator is adjusted mechanically by means of manually adjusting the nut of the regulator. For rinsing of the pressure regulator the adjusting nut must be set to a pre-determined value, so that the throttle

is fully opened.

Important: When exchanging the diaphragm it is to be made certain that the Teflon™-coated surface of the diaphragm points into the direction of the medium space.

4. Technical Data to top

| Denomination: | APSON Lacquer Pressure Regulator PRM-2000 |

| Media: | Lacquers, solvents, caustic solutions, a.o. |

| Medium pressure input: | max. 10 bar |

| Operating pressure output: | approx. 0 to 8 bar |

| Materials: |

|

| Medium links: | G1/4" |

| Dimensions: | Diameter 57 mm, Height 130 mm |

| Mass: | approx. 420 g |

5. Ordering Data to top

| Denomination | Part-Nr. |

| APSON Lacquer Pressure Regulator PRM-2000 | 040-A001 |

| APSON Lacquer Pressure Regulator Key (wrench width 54 mm) | 100-0105 |

Options:

-

All aluminum sections made of inoxidable steel