- About us

- Products

- Services

- Contact

=O=

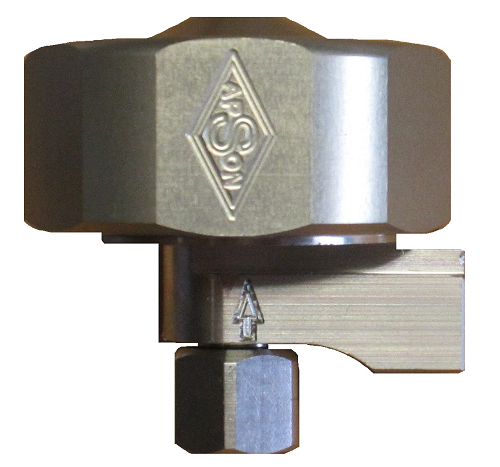

Lacquer Pressure Regulator PRP-2001, pneumatic

1. Introduction to top

The APSON Lacquer Pressure Regulator PRP-2001 is a pneumatically controllable pressure regulator for often to be changed aggressive media. It is particularly optimized for good rinsing barness and small solvent consumption. Therefore it is particularly

suitable to the application in automatic systems for the processing of lacquers, solvents, caustic solutions, a.o.

APSON Lacquer Pressure Regulator PRP-2001-G (G=straigth outlet)

2. Features to top

-

Environmental carefully due to short rinsing times.

-

Very good rinsing barness and small solvent consumption.

-

Small pressure losses.

-

Increased security due to application of a double diaphragm.

-

Rational maintenance and spareparts holding.

-

Very fast exchange of a defective double diaphragm (2 minutes).

-

Simplest handling at assembling, adjustment and maintenance.

-

Small, compact size.

3. Structure & Function to top

The APSON Lacquer Pressure Regulator PRP-2001 is equipped with a spacer ring with two diaphragms, a medium diaphragm and a pneumatic air diaphragm. The gap thus developing between the diaphragms has an outlet and serves for safety. The double diaphragm

separates the control pneumatic air from the medium.

The regulator keeps the medium pressure at the output constant and independent of pressure fluctuations of the medium supply system at the input of the pressure regulator, if the medium input pressure is higher than the preset required medium output pressure.

APSON PRP-2001 (with horizontal outlet) -- Structure

Legend: 1 = Medium input, 2 = Input connector, 3 = Closing spring, 4 = Lower casing part, 5 = Sealing ball, 6 = Sealing ring, 7 = Thrust piece, 8 = Medium diaphragm, 9 = Spacer ring, with vent hole, 10 = Pressure

air diaphragm, 11 = Spacer nut, 12 = End nut, 13 = Upper casing part, 14 = Plug-in connection, 15 = Pneumatic input, 16 = Overthrow nut, 17 = Pneumatic chamber, 18 = Centering pin, 19 = Vent hole, 20 = Lacquer chamber, 21 = Medium

output.

If a damage to the medium diaphragm takes place with still perfect control air diaphragm, then the medium penetrating into the diaphragm gap is derived by the outlet of the intermediate spacer ring.

If a damage to the control air diaphragm takes place with still perfect medium diaphragm, then control air penetrating into the diaphragm gap is derived by the outlet of the intermediate spacer ring.

At normal operation of the pressure regulator, penetration of medium into the pneumatics system can be prevented even with defective medium diaphragm. Due to the fluidodynamical clean interior geometry of the pressure regulator, a very short rinsing procedure

time is achieved.

The desired medium pressure at the output of the pressure regulator is adjusted pneumatically with the control air pressure. The regulation procedure is achieved through the equilibrium of the force produced by the control air pressure on one hand, and

the force produced by the medium pressure together with the strength of the recoil spring in the supply drilling of the medium chamber on the other hand. For rinsing of the pressure regulator, the control air pressure must

be set to a pre-determined value, so that the throttle in the supply drilling is fully opened.

Important: When exchanging the diaphragms it is to be made certain that the Teflon™-coated surface of the diaphragms point both into the direction of the medium space.

4. Technical Data to top

| Denomination: | APSON Lacquer Pressure Regulator PRP-2001 |

| Media: | Lacquers, solvents, caustic solutions, a.o. |

| Medium pressure input: | 0 to 20 bar (dependent on the control air pressure) |

| Operating pressure output: | approx. 1 to 16 bar |

| Control air pressure: | 0 to 16 bar (dependent on the medium pressure at the input) |

| Materials: |

|

| Control air link: | G1/8" |

| Medium links: | G1/4" |

| Spacer gap outlet: | Drilling with M5 thread (see Ordering-Options) |

| Dimensions: |

|

| Mass: | approx. 260 g |

5. Ordering Data to top

| Denomination | Part-Nr. |

| APSON Lacquer Pressure Regulator PRP-2001 with normal diaphragm | 040-A002 |

| APSON Lacquer Pressure Regulator PRP-2001 with waved* diaphragm. | 040-A005 |

| APSON Lacquer Pressure Regulator PRP-2001 with waved* diaphragm, straigth outlet. | 040-A005-G |

| APSON Lacquer Pressure Regulator PRP-2001 (MW, EVK90°G1/4, AHK90°G1/4): Diaphragm waved*; Inlet vertical, conical 90°, G1/4"; Outlet horizontal, conical 90°, G1/4" | 040-A005-H |

| APSON Lacquer Pressure Regulator Key (wrench width 54 mm) | 100-0105 |

* = Low Hysteresis.

Options: All aluminum sections made of inoxidable steel.

Spacer gap outlet link M5 for hose D = 4 mm, d = 3 mm.

Options: All aluminum sections made of inoxidable steel.

Spacer gap outlet link M5 for hose D = 4 mm, d = 3 mm.