-

About us

- Products

- Services

- Contact

=O=

Backflow Control Valve BCV-2011-P, Pneumatically

Prospect ~ 0.08 MBDownload

1. Introduction to top

The APSON Backflow Control Valve

BCV-2011-P is a pneumatically adjustable

pressure relief valve. It is particularly suitable for aggressive media,

e.g. varnishes, solvents, alkalis, a.o. The control valve releases the

flow to the output as long as the medium pressure at the input exceeds a

preset value. It is optimized for good rinsing and is intended for use in

painting plants, for lacquer back pressure control or as a dynamic bypass

in automatic systems.

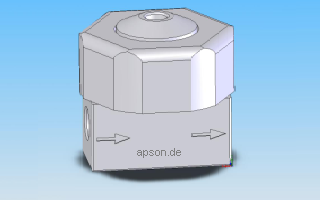

Fig. 1: APSON Backflow Control Valve BCV-2011-P

2. Features to top

-

Environmental carefully due to short rinsing times.

-

Good rinsing and low solvent consumption.

-

Efficient maintenance and spare parts inventory.

-

Very fast replacement of a defective diaphragm (approx. 2 minutes).

-

Easy handling during installation, adjustment and maintenance.

-

Very compact design.

3. Structure and Function to top

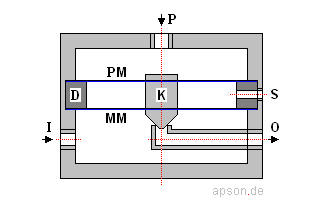

The APSON Backflow Control Valve

BCV-2011-P is equipped with a spacer ring D and two ondulated membranes (diaphragms), a

medium membrane MM and a control air

membrane PM (see Fig. 2). The resulting

gap space between ring and membranes has a radial output S. It is used as a safety device. The double

diaphragm separates the control air from the use medium and is equipped

with a sealing piston K. The backflow

control valve keeps the medium pressure at the inlet (!) constant and

independent of pressure changes of the medium-supply system as long as the

force acting on the piston K force due to the medium pressure at the input

is greater than the opposing force acting on the piston due to the

pneumatic pressure.

In the Normal Case resp. Normal

Mode, the input and the output result according to the arrow

direction. For special applications with higher working pressures the

APSON Back Flow Control Valve BCV-2011-P

can also be operated in Inverse Mode

(input and output against the arrow).

Occurs a damage to the medium membrane

MM at still perfect control air membrane, then the use medium

penetrating the membranes interspace is derived through the discharge

opening S. Occurs a damage to the control air

membrane PM at still perfect medium membrane, then the control

air penetrating into the membranes interspace is discharged through the

outflow opening S of the interspace.

Fig. 2: APSON Backflow Control Valve BCV-2011-P -- Functional

Scheme

With proper operation of the control valve, the advance of use

medium into the pneumatic system can be prevented in case of failure. The

flow geometry of the valve interior gives a very brief rinse. The desired

pressure of the use medium at the input of the control valve is adjusted

by means of pneumatic control air pressure.

Note: When replacing a diaphragm,

make sure that the Teflon™-coated surface of the diaphragm is mounted

towards the use medium.

4. Technical Data to top

| Designation: | APSON Backflow Control Valve BCV-2011-P |

|---|---|

| Use media: | Lacquers, solvents, alkalis, a.o. |

| Maximum working pressure: | Normal Mode: 12 bar, Inverse Mode: 20 bar |

| Max. throughput (with water): | Normal Mode: 20 l/min, Inverse Mode: 30 l/min |

| Materials: |

Wetted parts are stainless steel. Nut and cap made of

high-strength aluminum, hard anodized. Membranes made of rubber with

fabric portion, Teflon™ -coated.

|

| Pneumatic connection: | G1/8" |

| Use media connections: | G1/4" with 90° sealing cone |

| Dimensions: | Diameter 57 mm, height 66 mm |

| Mass: | Approx. 270 g |

5. Ordering Data to top

| Designation | Ordering Nr. |

|---|---|

| APSON Backflow Control Valve BCV-2011-P | 040-A027E |

| APSON Spare parts / consumable package for APSON BCV-2011-P | 300-0077 |

| APSON Paint pressure regulator key (wrench size 54 mm) | 100-0105 |

Options: All aluminum parts of stainless steel