- About us

- Products

- Services

- Contact

=O=

Hose Swivel Connectors

ProspectDownload

1. Introduction to top

APSON Hose-Swivel-Connectors are

mainly used in the coatings industry.

They connect normal paint and solvent hoses with standard

valve blocks and paint changers or with other

connectors with compatible dimensions.

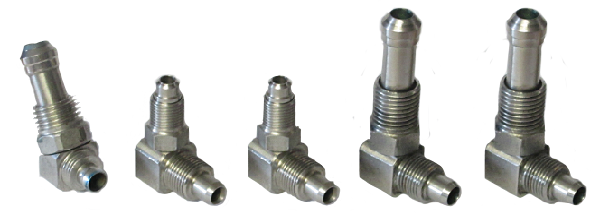

APSON Hose-Swivel-Connectors (a selection without hose-nuts)

2. Features to top

- Robust construction, large throughput and good flushability.

- Compatible with all block types according to the drawings of the following sections.

- Quasi-linear throughput rates at pressure changes (for curved connectors).

- Compact dimensions (for angled connectors).

3. Structure and Function to top

APSON Hose-Swivel-Connectors are

usually made of stainless steel and are brazed or welded, depending

on the type. Basically, they are available in two versions:

angled or bent .

Due to their construction they allow connections with different

connection blocks, tube diameters, deflection angles and swivel directions.

The desired swivel direction can be adjusted by tightening the nut.

For each connector the to be ordered hose nut is dependent on the

outer diameter of the hose provided.

Hoses and fittings as installed, can still hold residual pressure

and / or medium (paint, solvent, alkali, o.a.) even after system shutdown.

Before handling these parts, make sure they are completely emptied,

rinsed and with absolutely no pressure.

The relevant safety regulations (fire protection, explosion protection,

wearing of appropriate goggles, masks, gloves, protective clothing, etc.)

must be followed.

In the following, the hose swivel connectors are mainly classified according to:

-

Type of the deflection angle : angled or curved.

-

Size of the deflection angle : 90° right angle, 120° obtuse, or other angle.

-

Type of the thread : Inches or metric.

-

Type of sealing surface : 90° conical or 170° resp. 180° "flat".

Main advantage of the angled

connectors is their compact type.

Main advantage of the bent connectors is

their quasi-linear behavior of the throughput rates

at pressure changes.

Hose swivel connectors for tubes with small diameters

usually have smooth connection ports.

Some hose swivel connectors for tubes with larger diameters have

bulged ports for secure attachment.

At the customer request there are also available connectors with

different dimensions according to customer specifications.

APSON Hose Swivel Connectors - General dimensions

Legend: SW = nut wrench size, G = nut thread, L.. = length ..

4. Ordering Data to top

Annotations:

- The desired hose nut (last column) is additionally to be ordered, because it is not always clear (some nuts can fit on various connectors, depending on the outer diameter of the tube).

- Standard material is stainless steel 1.4305. Parts of other materials or other technical data are available according to customer specification.

5. G1/8" Rectangular to top

| Ord.-Nr. (1 of 2) | Thread G | Sealing Surface | Deflection Angle | SW [mm] | Hose Ø [mm] | L1 [mm] (approx.) | L2 [mm] (approx.) | L3 [mm] (approx.) | Hose Nut, Ord.Nr. (2 of 2) |

|---|---|---|---|---|---|---|---|---|---|

| 100-0933 | G1/8" | 90°, conical | 90°, rectangular | 11 | 6x8 | 35 | 13 | 27 | 100-0118 |

| 100-0557 | G1/8" | 90°, conical | 90°, rectangular | 11 | 6x8 | 35 | 13 | 22 | 100-0558 |

| 100-0557 | G1/8" | 90°, conical | 90°, rectangular | 11 | 6x9 | 35 | 13 | 22 | 100-0559 |

| 100-0665 | G1/8" | 90°, conical | 90°, rectangular | 11 | 9x12 | 63 | 13 | 22 | 100-0597 |

| 100-0666 | G1/8" | 90°, conical | 90°, rectangular | 11 | 6x12 | 63 | 13 | 22 | 100-0597 |

| 100-1429 | G1/8" | 90°, conical | 90°, rectangular | 11 | 4x6 | 35 | 13.5 | 23 | 100-1430 |

6. G1/4" Rectangular to top

| Ord.-Nr. (1 of 2) | Thread G | Sealing Surface | Deflection Angle | SW [mm] | Hose Ø [mm] | L1 [mm] (approx.) | L2 [mm] (approx.) | L3 [mm] (approx.) | Hose Nut, Ord.Nr. (2 of 2) |

|---|---|---|---|---|---|---|---|---|---|

| 100-0560 | G1/4" | 90°, conical | 90°, rectangular | 14 | 6x8 | 60 | 13 | 22 | 100-0558 |

| 100-0560 | G1/4" | 90°, conical | 90°, rectangular | 14 | 6x9 | 60 | 13 | 22 | 100-0559 |

| 100-0169 | G1/4" | 90°, conical | 90°, rectangular | 14 | 8x12 | 45 | 13 | 25 | 100-0170 |

| 100-0698 | G1/4" | 90°, conical | 90°, rectangular | 14 | 6x12 | 63 | 13 | 22 | 100-0200 |

| 100-0693 | G1/4" | 90°, conical | 90°, rectangular | 14 | 9x12 | 63 | 13 | 22 | 100-0200 |

| 100-0947 | G1/4" | 90°, conical | 90°, rectangular | 14 | 6x8 | 45 | 13 | 25 | 100-0118 |

| 100-0949 | G1/4" | 90°, conical | 90°, rectangular | 14 | 8x10 | 45 | 13 | 25 | 100-0150 |

| 100-1319 | G1/4" | 170°, "flat" | 90°, rectangular | 14 | DN6 | 41 | 15 | 35 | 100-1314 |

| 100-1320 | G1/4" | 170°, "flat" | 90°, rectangular | 14 | DN4 | 41 | 15 | 35 | 100-1317 |

7. G1/4" Obtuse to top

| Ord.-Nr. (1 of 2) | Thread G | Sealing Surface | Deflection Angle | SW [mm] | Hose Ø [mm] | L1 [mm] (approx.) | L2 [mm] (approx.) | L3 [mm] (approx.) | Hose Nut, Ord.Nr. (2 of 2) |

|---|---|---|---|---|---|---|---|---|---|

| 100-0219 | G1/4" | 90°, conical | 120°, optuse | 14 | 4x6 | 45 | 13 | 20.5 | 100-0220 |

| 100-0197 | G1/4" | 90°, conical | 120°, obtuse | 14 | 6x8 | 45 | 13 | 20.5 | 100-0118 |

| 100-0197 | G1/4" | 90°, conical | 120°, obtuse | 14 | 6x9 | 45 | 13 | 20 | 100-0198 |

| 100-0585 | G1/4" | 90°, conical | 120°, obtuse | 14 | 6x8 | 45 | 15 | 20 | 100-0118 |

| 100-0585 | G1/4" | 90°, conical | 120°, obtuse | 14 | 6x9 | 45 | 15 | 20 | 100-0198 |

| 100-0199 | G1/4" | 90°, conical | 120°, obtuse | 14 | 9x12 | 49 | 16 | 20 | 100-0200 |

| 100-0599 | G1/4" | 90°, conical | 120°, obtuse | 14 | 9x12 | 46 | 16 | 17 | 100-0200 |

| 100-0948 | G1/4" | 90°, conical | 120°, obtuse | 14 | 8x10 | 45 | 16 | 20 | 100-0150 |

8. Swivel Adaptors 90° to top

| Ord.-Nr. (1 of 2) | Thread Gi | Thread Ga | Sealing Surface | Deflection Angle | SW [mm] | DN | L1 [mm] (approx.) | L2 [mm] (approx.) | L3 [mm] (approx.) |

|---|---|---|---|---|---|---|---|---|---|

| 100-1321 | G1/4" | G1/4" | 170°, "flat" | 90°, rectangular | 14 | DN4 | 41 | 15 | 25 |

| 100-1322 | G1/4" | G1/4" | 170°, "flat" | 90°, rectangular | 14 | DN6 | 41 | 15 | 25 |

9. Arced Connectors to top

| Ord.-Nr. (1 of 2) | Thread G | Sealing Surface | Deflection Angle | SW1/SW2 [mm] | Hose Ø [mm] | L1 [mm] (approx.) | L2 [mm] (approx.) | L3 [mm] (approx.) | Hose Nut, Ord.Nr. (2 of 2) |

|---|---|---|---|---|---|---|---|---|---|

| 100-1327 | G3/8" | 170°, "flat" | 90°, Arc | 19/27 | 12x18.5 | 51 | 15 | 67 | 100-1315 |

| 100-1327 | G3/8" | 170°, "flat" | 90°, Arc | 19/27 | 12x20 | 51 | 15 | 67 | 100-1337 |

| 100-1327 | G3/8" | 170°, "flat" | 90°, Arc | 19/27 | 12x20.5 | 51 | 15 | 67 | 100-1456 |

10. Arced Adaptors to top

| Ord.-Nr. | Thread Gi | Thread Ga | Deflection Angle | SW1/SW2 [mm] | DN1 / DN2 | L1 [mm] (approx.) | L2 [mm] (approx.) | L3 [mm] (approx.) | L4 [mm] (approx.) |

|---|---|---|---|---|---|---|---|---|---|

| 100-1409 * | G1/4" x 180° | G1/4" x 170° | 160°, Arc | 14/17 | DN6 / DN6 | 86 | 13 | 58 | 40 |

| 100-1348 # | G3/8" x 180° | G3/8" x 170° | 180°, Arc | Special § | DN10 / DN13 | 100 | 9.5 | 70 | 30 |

*DCU, #ACU, § APSON Special Key, Ordering Nr. Z100-1506