-

About us

- Products

- Services

- Contact

=O=

Lacquer Changer LCM-2010 Mini

Prospect ~ 0.25 MBDownload

1. Introduction to top

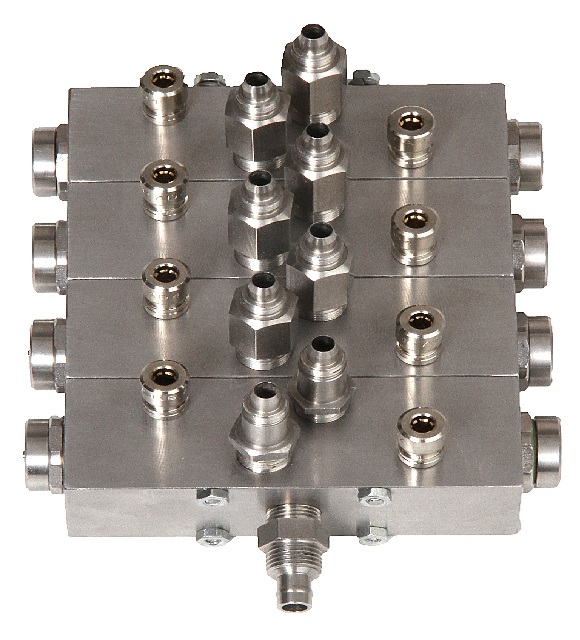

The APSON Lacquer Changer LCM-2010

Mini is a very compact paint changer for

aggressive, liquid working materials such as varnishes, solvents, alkalis.

Due to its construction and the large throughput it is very well rinseable

and employable both for Universal Lacquers and

Metallic Lacquers. Furthermore, this paint changer

type is also useable as a flushable

distributor.

Due to the employed valve type with tandem piston, APSON Minivalve VNT-3011, the paint changer

is operateable with the standard pneumatics pressures

used in the industry.

APSON LCM-2010 equipped with APSON Minivalve VNT-3011

2. Features to top

-

Environmentally friendly due to very good rinseability and short flushing times.

-

Costs saving due to minimized material and solvent consumption.

-

Particularly compact and suitable for tight spaces.

-

Deadspace-free APSON Minivalves VNT-3011, rinsing- and throughput-optimized material channels.

-

Made of stainless steel, wear-resistant and resistant to alkalis and weak acids.

-

Extendable to the desired number of material inputs resp. varnishes.

-

Easy handling during installation and maintenance.

3. Structure and Function to top

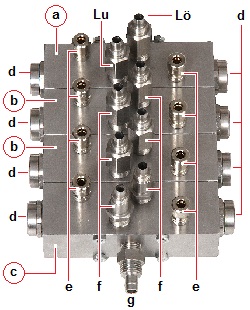

The APSON LCM-2010 consists of at least one purge

block (at the top), a variable number of

extension blocks (standard mini-valve blocks in

middle part), and an outlet block with central output

channel (at the bottom end). All valve blocks are screwed together and are

fitteable with maximum two mini-valves per block. For fixing the paint

changer, an angular profile is to be provided. In the following picture

the nuts of the hose connectors are not shown.

APSON LCM-2010 equipped with APSON Minivalves VNT-3011

Legend: a=purge block with a

connector for Lu=air and a connector for Lö=solvent (top most connector),

b=extension blocks, c=outlet block, d=mini valves, e=connectors for

pneumatic control, f=material inlets, g=material outlet.

4. Technical Data to top

| Denomination: | APSON LCM-2010 |

| Working materials: | Lacquers, solvents, alkalis, a.o. |

| Material pressure: | Max. 15 bar * |

| Pneumatic control pressure: | Approx. 6 – 8 bar * |

| Valve equipment: | 2/2-Ways APSON Minivalves VNT-3011 (for stub-conducts or ring-conducts with continuous material circulation) * |

| Materials: | Stainless steel, Viton™, Kalrez™, Teflon™ * |

| Working material inlets and outlet: | For hose D = 8 mm, d = 6 mm * |

| Dimensions unequipped, L x W x H: | Approx. 79 mm x 25 mm x 25 mm |

| Dimensions equipped, L x W x H: | Approx. 98 mm x 25 mm x 60 mm, together with valves and connectors |

| Mass, unequipped: | Approx. 300 g, per block, if made of stainless steel |

| Mass, equipped: | Approx. 370 g, per block, together with valves and connectors |

* Or according to customer specification.

5. Ordering Data to top

| Denomination | Order-Nr. |

|---|---|

| APSON Lacquer Changer LCM-2010 Mini (consisting of rinsing block, outlet block and a number of extension blocks, in accordance with clients request) | 050A___ |

| APSON Minivalve VNT-3011 | 060A060 |