-

About us

- Products

- Services

- Contact

APSON Products 2015.11.10

Catalogue ~ 6.3 MB Download

=O=

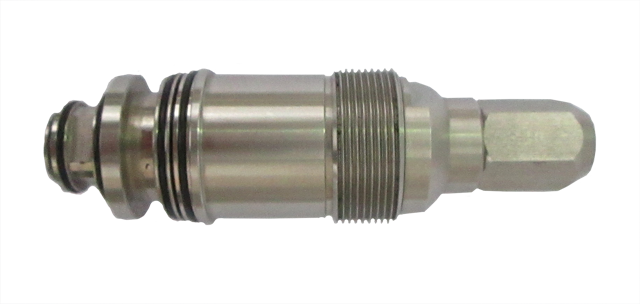

Minivalve VNT-3015

Prospect ~ 0.4 MBDownload

1. Introduction to top

The APSON Minivalve VNT-3015 is a

normally closed, pneumatically controllable 2/2-ways

tandem-valve for aggressive work materials, e.g. lacquers, solvents,

alkalis. It operates with the standard pneumatic pressures of the

industry. It is mainly used in special

applications as well as in APSON

SRS safety lacquer changers.

Fig. 1: APSON Minivalve VNT-3015

2. Features to top

-

Work material supply through hollow valve needle, casing very compact and smaller diameter.

-

Valve closes tight with the casing, thereby good rinsing in the valve block.

-

Compact 2-pistons tandem-valve, suitable for the standard pneumatic pressures of the industry.

-

Metallic parts made of stainless steel, seals are resistant against aggressive work materials.

-

Mounting in the valve block by pluggable connection and secured by locking screw.

-

Assembly and disassembly using simple tools.

3. Structure and Function to top

The APSON Minivalve VNT-3015 is a

normally closed 2/2-ways valve. The casing and parts

are made of stainless steel. The valve (see figure 2) mainly consists of a

cylindrical casing with one axial inlet and one axial outlet, for the work

material. Located inside the casing are three axially arranged chambers.

Through these chambers leads pressure-tight an axial, movable hollow valve

needle, at which two pistons and the main seal of the valve are fixed. The

pneumatic control air is supplied through the valve block.

The two chambers on the inlet side each contain

a pistons und are divided by them each into two partial-chambers - vent

chamber and pressure chamber. If the pressure chambers are charged with

compressed air, the valve opens. The air release is effected by

ventilation holes. Due to the tandem design, the pushing forces of the two

pistons sum. A compression spring in the first vent chamber closes the

valve as soon as it is no longer charged with compressed air.

The chamber on the outlet side is the real

valve chamber for switching of the work material. It has a sealing seat

and contains the output of the hollow valve needle (radial throughput

bores), as well as the main seal of the valve. The valve conducts the

working material through the hollow valve needle with good

throughput.

Fig. 2: APSON Minivalve VNT-3015 - Structure and Function

Legend: 1=inlet for work material,

2=hose connector, SL hose-nut, 3=work material, 4=hollow valve needle,

5=valve casing, 6=compression spring, 7=vent chambers, 8=pistons, 9=piston

seals, 10=pressure chambers, 11=control-air channel, 12=valve block,

13=inlet for pneumatic control air, 14=periferal locking groove,

15=throughput bores from hollow valve needle to the valve chamber,

16=valve chamber, 17=main seal of the valve (for better understanding of

the flow of the work material, the valve is shown in the activ,

open status), 18=sealing seat of the main seal, 19=outlet for

the work material, 20=valve needle seals, 21=ventilation bore holes,

22=case sealings, O-rings, 23=locking screw.

4. Technical Data to top

| Designation: | APSON Minivalve VNT-3015 |

|---|---|

| Valve type: | Normally closed, 2/2-ways |

| Work materials: | Solventborn and waterborn lacquers, solvents, alkalis, a.o. |

| Work material pressure: | Max 30 bar, hose-nut for hose [mm] d x D = 6 x 8 |

| Pneumatc control air pressure: | 6 to 8 bar |

| Casing parts: | Stainless steel |

| Main seal of hollow valve needle: | Kalrez™ |

| Seals for pistons and valve needle cone: | UHMWP (Ultra High Molecular Weight Polyethylene) |

| Casing sealings: | Viton™, or on customers request |

| Casing dimensions [mm] L x M: | Approx. 80 x M 24 |

| Mass: | Approx. 100 g |

| Approvals: | CE |

5. Ordering Data to top

| Designation | Ordering-Nr. |

|---|---|

| APSON Minivalve VNT-3015 | 060A070 |