- About us

- Products

- Services

- Contact

=O=

Thermotube TT-3008-Ex for Dynamic Applications

ProspectDownload

A regulated temperature of the spraying material - the

prerequisite for optimum painting

1. Introduction to top

The APSON Thermotube-3008-Ex is a

bending, flexible, temperable hose for transport of liquids and/or gases,

which, for optimum application, must be heated or be cooled - used

especially in Hazard Zones in the coatings industry, the chemical industry

or the food industry. Wherever stationary transport systems pass over into

moving systems (e.g. robots), the APSON Thermotube

TT-3008-Ex is the right solution.

APSON Thermotube TT-3008-Ex as well as APSON Thermotube

Interface TTI-3008

2. Features to top

-

Explosion-proof properties due to passive, external temperature control.

-

Robust, wear resistant, large temperature range.

-

Fittings made of stainless steel or according to customer requirements.

-

Environmentally friendly, low solvent losses (very good internal flushability).

-

For gaseous and/or liquid (solvent or water-based) paint materials.

-

Smooth outer surfaces, easy to clean, resistant to solvents.

-

Usable as heating and/or cooling hose.

3. Structure and Function to top

The APSON Thermotube TT-3008-Ex

consists of a flexible, wear-resistant, solvent-resistant,

temperature-resistant and form-resistant jacket hose enclosing

solvent-resistant transport hoses for the liquids and/or gases which are

to be transported (see the following figure). The jacket hose and

transport hoses are connected at the ends by means of a pressure-tight

connection fittings. The tempering of the application materials occurs by

pump P circulating a tempering medium

M from and to a tempering source

regulated by means of a temperature regulator R.

The flowback of the tempering medium M occurs directly through the jacket hose. For

optimal heat transfer as well as optimal kinematics the transport hoses in

the jacket hose are laid spirally (for simplification, this is not shown

in the figure).

APSON Thermotube TT-3008-Ex — Functioning Scheme

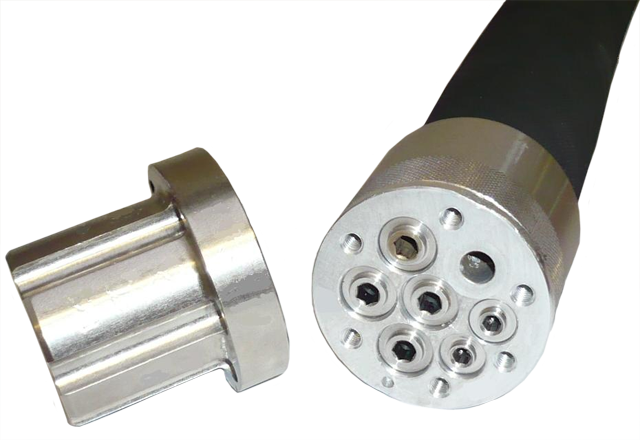

APSON Thermotube Interfaces TTI-3008

are provided with screws, and thus easy to install and dismantle. Special

hose connectors ensure a reliable tightness, even after many

disconnections of the parts.

4. Technical Data to top

| Designation: | APSON Thermotube TT-3008-Ex * |

| Working materials: | Lacquers, hardeners, alkalis, solvents, gases, a.o. |

| Tempering medium: | Water, glycol mixture, a.o. |

| Operating pressure of working materials: | Max. 10 bar |

| Operating pressure of tempering medium: | Max. 4 bar |

| Minimal bending radius: | Min. 30 cm |

| Temperature range of tempering medium: | 0 – 120 °C |

| Casing materials: | Plastics, Teflon™, stainless steel, light metal |

| Seals: | Viton™ |

| Connectors for working mterials (5): | For hoses, 3 times (6x8) mm and 2 times (4x6) mm |

| Connectors for tempering medium (2): | For hoses, 2 times (6x8) mm (flow and flowback) |

| Interface diameter: | Approx. Ø 100 mm, robot interface |

* Almost all technical data are also available according to

customer's request.

5. Ordering Data to top

| Designation | Ordering-Number |

|---|---|

| APSON Thermotube TT-3008-Ex ( 3500 mm = 2500 mm + 2 x 500 mm) * | 010A057 |

| APSON Thermotube TT-3008-Ex ( 2400 mm = 1400 mm + 2 x 500 mm) * | 010A058 |

| APSON Thermotube TT-3008-Ex ( 2900 mm = 1900 mm + 2 x 500 mm) * | 010A059 |

| APSON Thermotube TT-3008-Ex (11000 mm = 10000 mm + 2 x 500 mm) * | 010A060 |

| APSON Thermotube TT-3008-Ex ( 2220 mm = 1220 mm + 2 x 500 mm) * | 010A061 |

| APSON Thermotube TT-3008-Ex (please specify the required lengths) * | ####### |