-

About us

- APSON Products Catalogue 2014

- Services

- Contact

APSON Products 2014

Catalogue ~ 4.47 MB Download

Pulse Cleaner 2000

Prospect ~ 0.09 MBDownload

1. Introduction to top

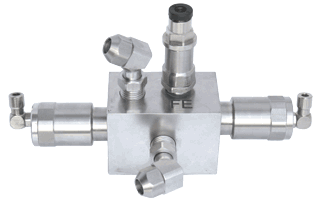

The APSON Pulse Cleaner 2000 is a pneumatically controllable

rinsing block for aggressive lacquers and solvents. It is the standard

cleanerblock designated for the modular APSON Lacquer Changer

2000 M.

APSON Pulse Cleaner 2000

The APSON Pulse Cleaner 2000 is particularly suitable for

automatic painting systems with often changing lacquers and serves for

rinsing the lacquer changer switch, the hoses and rotation atomizers

or spray guns. It avoids reliably a pollution of the newly connected

lacquer during the painting process and ensures thus a perfect lacquer

change.

2. Structure and Function to top

The APSON Pulse Cleaner 2000 consists of a block housing with an

output and one input each for solvent LM (LO) resp. compressed air LU.

The output side of the pulse cleaner forms a pressure tight interface

to the valve blocks of the lacquer change-over switch.

A pneumatically controllable valve is assigned to each input.

Due to that alternated control of the two valves, the opening times of

the valves can overlap. Therefore the connetion fittings of both

inputs (compressed air and solvent) contain an additional checkvalve

each.

During painting, solvent and compressed air pend permanently at

the pulse cleaner. For executing the rinsing cycle, the solvent

valve LF and the compressed air valve LLF are alternatingly opened,

starting with the solvent valve.

Due to this sequence, an alternating flow of air resp. solvent

develops, which rinses reliably the lacquer changer switch downstream

the hoses and other spray devices. The duration of the rinsing cycle

as well as the switching sequence of the two valves depend on the

conditions of the painting process and are to be controlled by means

of a programmable logic controller. The more briefly the switching on

impulses of the two valves (preferably smaller than 1 second), the

better the rinsing quality.

3. Features to top

-

Small solvent consumption for perfect rinsing.

-

Environmental careful short rinsing cycle due to high throughput.

-

Very good rinsing barness due to deathroom-minimized valve blocks.

-

The valves are compatible with the valves of the lacquer changer switch blocks.

-

Fast valve exchange due to screwable valve technique.

-

Pro-active maintenance possible due to leakage display of the valves.

-

Visible switching status of the valves.

-

Small, compact design.

4. Technical Data to top

| Denomination: | APSON Pulse Cleaner 2000 |

| Media: | Lacquers, solvents, caustic solutions, a.o. |

| Compressed air pressure: | 6 to 12 bar, see also solvent pressure. |

| Solvent pressure: | 6 to 12 bar, (1 to 1.5 bar higher than compressed air). |

| Valve assembly: | Two 2/2-ways valves, see Ordering Data. |

| Checkvalves: | Two checkvalves, see Ordering Data. |

| Valve switching pressure: | Min. 6 bar, max. 8 bar, measured at the valve. |

| Housing material: | Inoxidable steel, see Ordering Data. |

| Sealing material: | Viton™ |

| Control air link: | For hose, d = 2.7 mm, D = 4 mm |

| Compressed air input: | For hose, d = 6 mm, D = 8 mm |

| Solvent input: | For hose, d = 6 mm, D = 8 mm |

| Dimensions, block: | Length 59 mm, Height 30 mm, Depth 42 mm |

| Dimensions, complete: | Length 149 mm, Height 30 mm, Depth 47 mm resp. 97 mm |

| Mass of the block: | approx. 280 g |

| Mass, complete: | approx. 380 g |

5. Ordering Data to top

| Denomination | Quantity | Part-Nr. |

| APSON Pulse Cleaner 2000, complete | 1 | 070-A005 |

| APSON 2/2-Ways Valve 2000 | 2 | 060-A008 |

| APSON Checkvalve 2000 | 2 | 100-A001 |

Options:

-

1. Housing from aluminum, anodized.

-

2. Air/solvent connectors on customer's request.