-

About us

- Products

- Services

- Contact

APSON Products 2015.11.10

Catalogue ~ 6.3 MB Download

=O=

Secondary-Circuits Rinsinggroup CSC-2000

Prospect ~ 0.09 MBDownload

1. Introduction to top

The APSON Secondary-Circuits Rinsinggroup CSC-2000 serves to divide

long lacquer lines into individual rinsing segments. The resulting shorter segments can be rinsing cleaned

simultanely and independently. This leads to substantially

shorter rinsing cycles and to more flexible rinsing concepts.

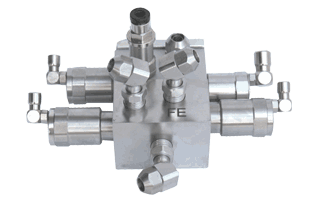

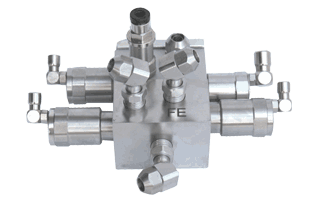

APSON Secondary-Circuits Rinsinggroup CSC-2000 in standard

execution

The APSON Secondary-Circuits Rinsinggroup CSC-2000 is particularly

suitable to applications in automatic systems for the processing of

lacquers, solvents, caustic solutions, a.o.

2. Features to top

-

Cost-saving because of short rinsing duration.

-

Optimal cleaning efficiency due to short rinsing segments.

-

Simplest handling at assembling and maintenance.

-

Fast and more easily exchange of the valves.

-

Deathroom-free valves and visible switching status.

-

Pro-active maintenance possible due to leakage display of the valves.

-

Compact housing with high throughput.

3. Structure to top

...#################

APSON Secondary-Circuits Rinsinggroup CSC-2000 -

Structure

A Secondary-Circuits Rinsinggroup 2000 in standard execution, is

shown in the above image. The group is build of:

-

Rinsing block (shown at bottom).

-

Switching block (shown at top).

The rinsing block in standard

execution has two pneumatically controllable 2/2-ways valves and two

checkvalves. As rinsing block alternatively installable types:

-

APSON Pulse Cleaner 2000 (standard rinsing block).

-

APSON Turbo-Pulse Cleaner 2001.

-

APSON Turbo Cleaner 2002.

The switching block has as

standard a pneumatically controllable 3/2-ways valve for the laquer enable

resp. laquer feedback. For special applications, e.g. preloadeable A-B

systems, the switching block is optionally available with a second

3/2-ways valve.

4. Function to top

...#####################

APSON Secondary-Circuits Rinsinggroup CSC-2000 -

Function

The following scheme shows en exemplaric Concept for laquer supply with a Secondary-Circuits

Rinsinggroup (SSG). The SSG divides the paint line mainly in

two segments:

-

Supply-sided segments I and II.

-

Atomizer-sided segment III with SSG.

The following mainly describes segment III with SSG. Segments

I and II are provided only for better understanding of the following

text.

APSON Secondary-Circuits Rinsinggroup 2000 - Functional

Scheme

Legend

During the painting process the

feedback link of the switching block FFS is closed. The laquer flows thus

through the switching block FFS to the atomizer Z.

During the rinsing cycle the

APSON Cleaner of the lacquer change-over switch LW becomes active and the

3/2-ways valve of the switching block FFF switches the supply sided hose

segment over its feedback link to the receptacle AB. The APSON Cleaner of

the APSON Secondary-Circuits Rinsinggroup SSG becomes simultaneous active

and rinses the mixture from lacquer, air and solvent of the atomizer-sided

hoses of segment III over the feedback valve of the atomizer into the

likewise receptacle AB.

5. Technical Data to top

| Denomination: | APSON Secondary-Circuits Rinsinggroup CSC-2000 |

|---|---|

| Media: | Lacquers, solvent, caustic solutions, a.o. |

| Medium pressure: | max. 12 bar |

| Rinsing block valves: | two APSON 2/2-Ways Valves |

| Switching bock valves: | one APSON 3/2-Ways Valve, see Options |

| Housing material: | Inoxidable steel |

| Seal materials: | Teflon™ and/or Viton™, * |

| Valve control air pressure: | 6 bar to 8 bar, measured at the valve |

| Control air pressure link: | for hose, D = 4 mm, d = 2.7 mm, * |

| Solvent link LM: | for hose, D = 8 mm, d = 6 mm, * |

| Pulsation air port PL: | for hose, D = 6 mm, d = 4 mm, * |

| Medium input FE: | for hose, D = 6 mm, d = 4 mm, * |

| Medium output: | for hose, D = 6 mm, d = 4 mm, * |

| Feedback port RF: | for hose, D = 8 mm, d = 6 mm, * |

| Dimensions without valves: | length 59 mm, width 42 mm, height 68 mm |

| Dimensions with valves: | length 124 mm, width 174 mm, height 88 mm |

| Houlder: | Support angle, * |

| Mass: | approx. 1.5 kg |

* or after customer's request

6. Ordering Data to top

| Denomination | Part-Nr. |

|---|---|

| APSON Secondary-Circuits Rinsinggroup CSC-2000 (with one 3/2-ways valve for laquer enable/feedback) | 050-A007 |

| APSON 2/2-Ways Valve 2000 (sparepart) | 060-A008 |

| APSON 3/2-Ways Valve 2004 (sparepart) | 060-A015 |

| APSON Checkvalve 2000 (sparepart) | 100-A001 |

Options:

-

Secondary-Circuits Rinsinggroup CSC-2000 with two 3/2-ways valves for laquer enable/feedback.

-

Secondary-Circuits Rinsinggroup CSC-2000 with APSON Turbo-Pulse Cleaner 2001.

-

Secondary-Circuits Rinsinggroup CSC-2000 with APSON Turbo Cleaner 2002.