-

About us

- Products

- Services

- Contact

APSON Products 2015.11.10

Catalogue ~ 6.3 MB Download

=O=

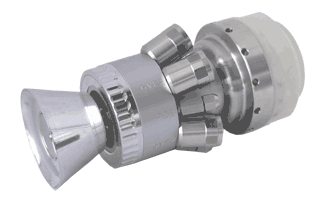

Sprayhead SH-2000

Prospect ~ 0.08 MBDownload

1. Introduction to top

The APSON 4M Sprayhead SH-2000 for high rotation atomizers is a

compact sprayhead with 4 medium valves. It is mainly designed for standard

spindle turbines used in the industry, but can be manufactured also after

customer's request.

APSON Sprayhead SH-2000 with valves and color tubing carrier

(base-body, valves, color tubing carrier and hose couplings are to be

ordered separately)

The APSON Sprayhead SH-2000 is particularly suitable for

applications in automatic systems with aggressive media, e.g. lacquers,

solvents, caustic solutions, a.o. Due to the construction and the high

throughput it is very well rinsable and applicable for lacquers based on

solvents, or on customer's request for water-based, metalic and filler

lacquers equally well in roof and side machines.

2. Features to top

-

Supply of up to 4 utilizable media directly in the sprayhead.

-

Environmental carefully due to minimum consumption of utilizable medium.

-

Environmental carefully due to shortest rinsing times.

-

Cost-saving due to minimized consumption of rinsing medium.

-

High throughput and very good rinsing barness.

-

Simple handling when assembling and in maintenance.

-

Deadthroomfree valves and media channels optimized for throughput and rinsing.

3. Structure and Function to top

The APSON Sprayhead SH-2000 consists of:

-

Sprayhead base body and air shower body for the medium links and valves for the utilizable medium,

-

Union nut for fastening the sprayhead body to the turbine case,

-

Unscrewable air guidance ring within the front area,

-

Exchangeable lacquer tubing carrier with unscrewable pneumatic air dissipator ring.

APSON Sprayhead SH-2000 - Operational Scheme

1=Turbine motor, 2=Turbine case, 3=Turbine bearings, 4=Turbine shaft, 5=Sprayhead body , 6=Disk seal, 7=Lacquer tubing carrier, 8=Atomizer/Bell, 9=Valves

The base body and the air shower body contain the drillings and

threads for the circularly arranged utilizable medium valves and medium

connections as well as the color tubing carrier. The color tubing carrier

leads the utilizable media and the rinsing medium into the bell.

Furthermore it prevents the penetration of liquid media into the front

turbine bearing and supplies the bell with compressed air during the

operation.

The seals and fixing bolts for the color tubing carrier are supplied

in a separate spare-part/-seal package (see Ordering Data). To each

utilizable medium valve (bell valve) GVF1 to GVF4 is assigned a utilizable

medium entrance (color entrance) per FE1 to FE4. Additionally the

sprayhead has still a vent hole and further four connections.

-

RL - Connection for ring-air/guidance-air (Ringluft/Lenkluft), serves for shaping the spraying cone

-

LG - Connection for solvent for the bell (Loesemittel fuer Glocke), serves for rinsing the spraying bell

-

FTL - Connection for the lacquer tubing carrier cleanholding air (Farbrohrtraeger Freihalteluft) prevents getting the bell dirty

-

FL - Connection for cleanholding air (Freihalteluft) prevents penetration of liquids into turbine bearings

4. Technical Data to top

| Denomination: | APSON Sprayhead SH-2000 |

|---|---|

| Media: | Lacquers, solvents, caustic solutions, a.o. |

| Media pressures: | max. 10 bar |

| Air pressures: | max. 12 bar |

| Materials: | Aluminum and brass (brass for the thread of the guidance-air dissipator) |

| Seals: | Viton compound™, or after customer's request |

| Dimensions (in mm): |

|

| Connections: |

* = Connections with PA sealing

ring

|

| Valves interfaces: | for APSON 2/2-Ways Valves, in accordance with Ordering Data |

| Color tubing carrier interface: | for APSON Lacquer Tubing Carrier, in accordance with Ordering Data |

| Fastening: | Union nut for turbine case, or after customer's request |

| Mass: | approx. 850 g, with union nut and union fittings, however without valves and color tubing carrier |

5. Ordering Data to top

| Denomination | Part-Nr. |

|---|---|

| APSON Sprayhead SH-2000, (without valves and lacquer tubing carrier) | 100-0500 |

| APSON 2/2-Ways Valve 2003 (accessory, 4 pieces) | 060-A011 |

| APSON Guidance air Ring for Sprayhead Body - sparepart | 100-0498 |

| APSON Union Nut for fastening to the Turbine Case - sparepart | 100-0226 |

| APSON Lacquer Tubing Carrier SHC-2000 for 4 media (accessory, 1 piece) | 100-0499 |

| APSON Pneumatic air dissipation Ring for Lacquer Tubing Carrier SHC-2000 - sparepart | 100-0501 |

| APSON Lacquer Tubing Carrier SHC-2000 for 4 media - sparepart package | 300-0014 |

Options:

-

Other dimensions for link and tubing screw connections

-

Sprayhead with more than 4 media inputs on customer's request