-

About us

- Products

- Services

- Contact

APSON Products 2015.11.10

Catalogue ~ 6.3 MB Download

=O=

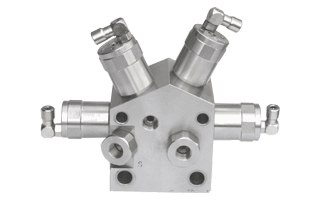

Pump Rinsingblock CPY-2000

Prospect ~ 0.09 MBDownload

1. Introduction to top

Through the attachment of the APSON Pump Rinsingblock CPY-2000 to

the rinsable types of the Barmag® lacquer pumps for 6 or optionally

3 ccm/revolution, the lacquer pumps can additionally be rinsed. This

enables a shorter rinsing cycle because the pump and the lacquer lines can

be rinsed at the same time. Thus shorter rinsing times are achieved with

better pump cleaning and more flexible rinsing concepts. The Pump

Rinsingblock CPY-2000 is particularly suitable to the application in

automatic systems for the processing of lacquers, solvents, caustic

solutions, a.o.

APSON Pump Rinsingblock CPY-2000

2. Features to top

-

Very effective cleaning of the pump, because this is additionally rinsable.

-

Cost-saving because of short rinsing times.

-

Compact housing due to direct surface mounting on the pump.

-

Simplest handling at assembling and maintenance.

-

Faster and more easily exchange of the valves.

-

Deathroom-free valves and visible switching status of the valves.

-

Pro-active maintenance possible due to leakage display of the valves.

3. Structure and Function to top

All valves are controlled pneumatically. The following pattern

clarifies the functional connection

APSON Pump Rinsingblock CPY-2000

Legend:

PUB = Pump Rinsingblock CPY-2000, MW = medium change-over switch, Z = atomizer, BYP = bypass valve, PL = pulsation air valve, RF = feedback valve, PU = pump, SK = sprayhead, AB = receptacle, Mx = medium valve x, LO = solvent valve

The APSON Pump Rinsingblock CPY-2000 consists of the following

components:

-

Inoxidable steel block as interface to the pump and for the accommodation of the valves and access links;

-

Bypass valve. Hereby the lacquer lines can be separated and be rinsed independently of the pump during the rinsing cycle;

-

A pulsation air valve and a solvent valve. These valves serve the pump for rinsing. During the rinsing cycle these two valves can be controlled alternatingly and rinse the pump with a mixture from air and solvent;

-

Reconducting valve for deriving the pump rinsing mixture into the receptacle;

-

Ever a checkvalve in the supply links of the pulsation air and the solvent. These prevent the penetration of solvent in the pulsation air supply or the penetration of compressed air into the solvent line during rinsing.

4. Technical Data to top

| Denomination | APSON Pump Rinsingblock CPY-2000 |

| Media | Lacquers, solvent, caustic solutions, a.o. |

| Medium pressure | max. 12 bar |

| Valve assembly | four APSON 2/2-Ways Valves 2000 |

| Material | Inoxidable steel |

| Seal materials | Teflon™, Viton™-compound, or after customer's request |

| Valve control air pressure | min. 6 bar upto max. 8 bar, measured at the valves |

| Control air link | for hose, D = 4 mm, d = 2.7 mm, or after customer's request |

| Solvent link LM | for hose, D = 8 mm, d = 6 mm, or after customer's request |

| Pulsation air port PL | for hose, D = 8 mm, d = 6 mm, or after customer's request |

| Bypass port BY | for hose, D = 6 mm, d = 4 mm, or after customer's request |

| Medium output | for hose, D = 6 mm, d = 4 mm, or after customer's request |

| Feedback port RF | for hose, D = 8 mm, d = 6 mm, or after customer's request |

| Dimensions (in mm) |

|

| Attachment | directly on the pump |

| Mass | approx. 1.5 kg |

5. Ordering Data to top

| Denomination | Part-Nr. |

|---|---|

| APSON Pump Rinsingblock CPY-2000, completely (for the rinsable Barmag® pump with 6 ccm/revolution) | 030-A001 |

| APSON 2/2-Ways Valve 2000 (sparepart) | 060-A008 |

| APSON Checkvalve 2000 (sparepart) | 100-A001 |

Options:

-

Adapter for attaching to the rinsable Barmag® pump for 3 ccm/revolution