- About us

- Products

- Services

- Contact

=O=

Lacquer Changer LCLT-25K4 Inline

Prospect Download

1. Introduction ^^ to top

The APSON Lacquer Changer LCLT-25K4

Inline is a modular expandable switching unit for pressurized

chemically aggressive work materials, e.g. paints, solvents, alkalis. It

is an evolution of the standard lacquer changer type and belongs to the

class of inline paint changers with large inline throughput for many

delivery points. The paint changer consists of a maximum of 23 switching

blocks. Each block is provided with 1 throughput

channel (inline channel) and 4 independent output channels

(A-B-C-D). Each output channel of a block is independent of the

other output channels and can be fitted with pneumatically controlled

APSON valves or APSON locking screws. This lacquer changer type is also

deliverable as piggable/newteable

execution (APSON LCLT-25K4- N, Lacquer

Changer for recovering the residual amounts).

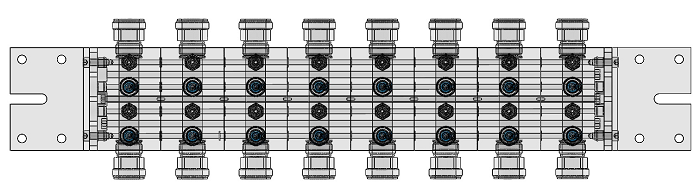

FigAbb. 1: APSON LCLT-25K4 Inline for 8 lacquers (max. 23 lacquers)

Due to the multi-channel, economical A-B to

A-B-C-D systems or special applications are realisable. All

four output channels can be switched through to the same paint, or any

output channel can be switched through to a different paint. The piggable

execution of the paint changer allows coating processes without work

breaks (back pushing of the residual quantities, flushing the lines,

re-charging with new work material), because the inactive part of the

system can be used for recovering the residual amounts of old paint type

and for pre-charging with a new type of paint, while a different part of

the system is producing.

The piggable APSON LCLT-25K4-N

enables almost complete recovery of the residual amounts by back pushing

the work material from the supply lines and paint changers into the supply

system. It offers large material throughput and allows, due to the

construction and the used dead-space-minimized APSON valve technology,

very good rinsing of both, the supply lines as well as the output lines of

the paint system.

2. Features ^^ to top

- Large inline throughput and very good rinsing, N-version is piggable.

- Environmentally friendly due to short rinsing times and work material recovery (N version)

- Modular expandable to the desired number of media (up to 23 blocks).

- Dead-space-minimized valves, and rinsing- and throughput-optimized ducts.

- Cost-saving due to 4 channels and minimal work material consumption.

- Easy handling during installation and maintenance.

- Material: Stainless steel, therefore durable and wear resistant.

- Resistant to alkalis and weak acids.

3. Structure and Function ^^ to top

The APSON LCLT-25K4 Inline consists

of a maximum of twenty-three switch blocks, each with a large inline

channel (DN25) and with four output channels (A, B, C, D). The uppermost

block and the lowermost block (end blocks) are special blocks for

assembling and fixing the paint changer and for connecting the output

channels. Long lacquer changers with more than 11 blocks have a special

block (center block) with threaded holes for assembly by means of threaded rods.

Each block has four screw sockets for pneumatically controllable

APSON 2/2-ways valves. Thus allows per block, that the associated inline

channel can be switched through to max. four output channels. The blocks

have to each one end of the output channel one O-ring (per channel) for

sealing the adjacent blocks, and two pins for aligning the blocks when

assembling the paint changer. The components are made as standard of

stainless steel. For rinsing (rinse cycle), the respective valves of an

external cleaner group supply several times alternately, for a short time

air and solvent into the to be rinsed output channel of the paint changer.

Fig. 2: APSON LCLT-25K4 -- Functional Scheme (example with 2 lacquer changers)

Legend: A, B, C, D = output

channels, V = 2/2-way valves, L.. = paint or work medium, PL.. = control

air for lacquer valves (pneumatic), PU = pump, PR = pressure regulator /

pressure limitor, RS = loop system (example for decanting work media), TS

= stub system (example), T = screw plug.

4. Technical Data ^^ to top

| Denomination | APSON Lacquer Changer LCLT-25K4 Inline, without pipe and hose fittings (or according to customer's requests) |

| Media | Lacquers, solvents, alkalis, weak acids, etc. |

| Number of blocks | Maximal 23 blocks |

| Material pressure | Maximal 15 bar |

| Valve assembly (optional) | APSON 2/2-Ways Valves LV 2014-6P, dead-space-minimized valve technology, arrangement and assembly according to customer's requests |

| Materials | Stainless steel |

| Seals | Viton™, or according to customer's request |

| Inline passages | DN25, for pipe connections, or according to customer's requests |

| Connections for paint | G1", or reduced, according to customer's request |

| Connections for air, solvent | G1/4", for hose D × d = 8 × 6 mm, or according to customer's request |

| Dimensions of one block Lenght × Width × Height |

70 × 130 × 80 mm (without valves and fittings) |

| Mass | Approx. 5.2 kg per block |

5. Ordering Data ^^ to top

| Denomination | Part- Number |

| APSON Lacquer Changer LCLT-25K4, without pipe and hose fittings. Number of paints or special designs according to customer's request. | 050-A297 |

| APSON Lacquer Changer LCLT-25K4-N, Piggable, without pipe and hose fittings. Number of paints or special designs according to customer's request. | 050-A297-1 |

| APSON 2/2-way valve lacquer LV-2014-6P (spare parts) | 060-A039-6 |

| APSON screw plug VS-2008 (spare part) | 100-0886 |