- About us

- Products

- Services

- Contact

=

O

=

Lacquer Changer SR-24 Intrinsic

Prospect Download

1. Introduction to top

Standard Lacquer Changers are usually built as a series of bolted together valve blocks, with one common continuous output channel along through the assembly. A standard valve block has two inputs, each with

a valve for switching media (paint, solvent, compressed air) to the output channel. If one or more media valves leak unnoticed, they can, during painting, also feed wrong media into the output channel. The painted object thus

receives a wrong color and causes unnecessary costs because it must be repainted. Furthermore, in paint systems with paint circulation and different supply pressures, costly paint and/or solvent interference can occur.

The APSON SR-24 Lacquer Changer solves this problem reliably. It is an intrinsically safe rotative lacquer changer constructed so that its output is during painting exclusively connected to a single paint input.

That's why paint contamination with other media is excluded. The lacquer changer is intended for industrial painting equipment and is suitable for solvents, compressed air and lacquers based on solvent or water. It enables

fast and safe lacquer changes as well as economic rinses with only a small amount of solvent.

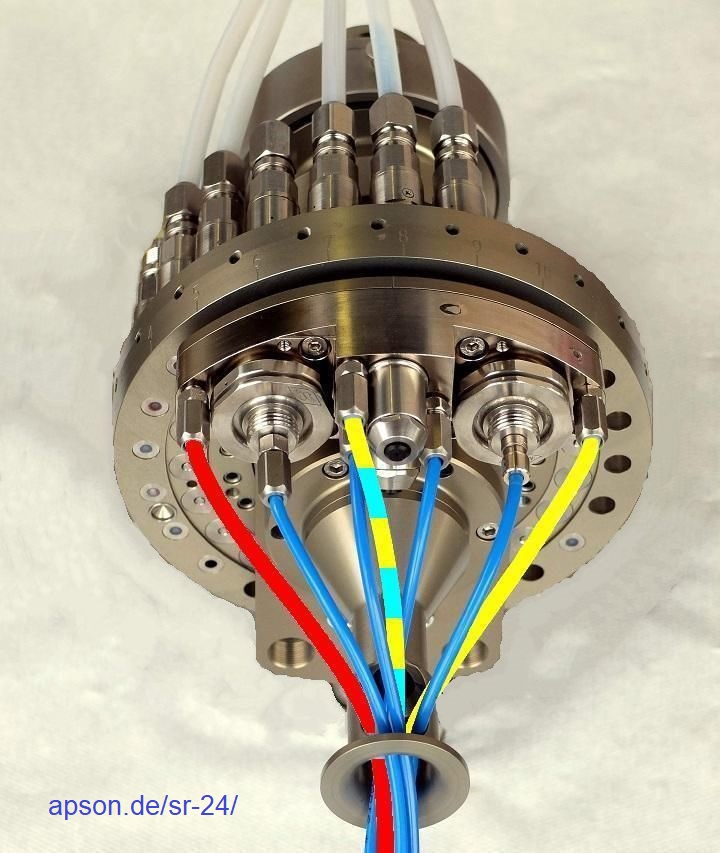

APSON Lacquer Changer SR-24 Intrinsic (Patented)

2. Features to top

-

Intrinsically safe - an in-scattering of unwanted media is certainly excluded.

-

Lacquer changer with small outer diameter and max. 24 mini lacquer valves.

-

Only one control hose for all lacquer valves (APSON Patent) - saves electronics and hoses.

-

Lacquer valves with tandem pistons - allow compact design and lower consumption of compressed air.

-

Each lacquer valve allows lacquer supply via stub or circulation hose.

-

Hot-swappable lacquer valves (for stator) can be removed without opening the media path (option).

-

Large throughput, good flushability, short flush times - environmentally friendly.

-

Pressure regulators and switching valves are located on the needle bearing mounted rotor.

-

Enables short hose to pump / spray head - results in minimal flushing losses.

3. Structure and Function to top

The APSON SR-24 Lacquer Changer is intended for a maximum of 24 lacquers. He has a maximum diameter of 180 mm and consists of adapter, coupling, optional a homing disc and sensor, holder, stator and "rotor". The Adapter,

Coupling and the Holder are to be specified by the customer. The homing disc RD and the homing sensor RS are optional. These are intended for fast automatic homing. The Stator consists of

one pneumatic cylinder, a drive shaft and a valve ring with the holes for safe engagement of the rotor in the position of the to be controlled lacquer valve.

APSON Lacquer Changer SR-24 Intrinsic -- Structure and Function

The Pneumatic Cylinder is used for docking or undocking the Rotor. It is equipped with two pneumatic connections H1 resp. H0 for actuation of the pneumatic cylinder by means of compressed air, as well as with

two sensors to clearly identify whether the rotor is docked or undocked. Of the pneumatic cylinder contains a pneumatically displaceable piston K with hollow piston rod to which the rotor is rotatably mounted.

The Valve Ring contains the holes for attaching the lacquer valves LV and a common annular channel P for the compressed air for controlling the paint valves. Each paint valve can be connected to one circulation

line U or a stub line S. The control of the desired paint valve is done in three steps: 1. Position the rotor. 2. Dock the rotor for mechanically actuating the associated compressed air release valve FV on the stator via pin

FP on the rotor. 3. Release the compressed air P for activating of the paint valve. In the case of applications with higher paint pressure only a single pressure booster is required for all paint valves. Valve units for controlling

the paint valves are not required.

The Rotor is supported by needle bearings and is both sliding as well as rotatable. He has a release pin FP and contains media channels for painting, push-out and rinsing by means of a sequence of air LU and

solvent LÖ. By means of push-out, the paint between rotor and return valve RFV in the atomizer can almost completely be used for painting (see picture). On the rotor are also the media release valves SV and pressure regulator

DR for rinsing, as well as for the push-out. The volume to be set, or the gate time to be set for the push-out, depends on the properties of the respective lacquer to be expressed, as well from the pressure of the medium used

for the push-out.

4. Technical Data to top

| Denomination: | APSON Lacquer Changer SR-24 Intrinsic |

| Media: | Water- and solvent-based metalic and standard lacquers, solvent, pressure air, alkalis. |

| Media temperature: | Approx. +5 .. +35 °C. |

| Media pressure: | Approx. 8 bar (max. 20 bar, if pneumatic booster is necessary). |

| Control pressure: | Approx. 8 bar (max. 16 bar through booster, if a higher lacquer pressure is necessary). |

| Maximal positioning duration: | Approx. 1 second, for the standard rotor and acceleration of approx. +/- 60 rps/s [1/s²], for traveling 23 positions (e. g. from pos. 1 to pos. 24). |

| Duration of lacquer change: | Approx. 10 .. 15 seconds, depending on lacquer, solvent, their pressure, etc. |

| Lacquer valves: | Maximal 24 Mini Lacquer Valves with tandem piston, for the stator. |

| Control valves: | 2 normal pneumatic controllable valves with tandem piston, for the rotor. |

| Pressure regulators: | 2 pneumatically controllable mini pressure regulators, for the rotor. |

| Lacquer connectors: | For lacquer hose, Ø 3x6 mm. |

| Control connectors: | For pneumatic hose, Ø 2x4 mm. |

| Mass and Dimensions: | Approx. 7 kg, Length approx. 300 mm, Ø 180 mm (without holder, motor, coupling). |

5. Ordering Data to top

| Product Denomination | APSON Ordering Nr. |

| APSON Lacquer Changer SR-24 Intrinsic | 050A307 |

| APSON SR-24-RLV Lacquer Valve for the Rotor | 060A060-7 |

| APSON SR-24-RPR Pneumatical Mini Lacquer Pressure Regulator for the Rotor | 040A035-40 |

| APSON SR-24-SLV Mini Lacquer Valve, for the Stator | 060A070-8 (!) |

| APSON SR-24-SLVP Mini Lacquer Valve with actuatorpin for connectors with blocking function, for the Stator | 060A070-81 |

| APSON SR-24-YU Hose-Y-Connector for Circulation, 6x9 .. 4x6 mm | 100A027 |

| APSON SR-24-YUB Hose-Y-Connector for Circulation, 6x9 .. 4x6 mm, with integrated blocking function (only for Lacquer Valve 060A070-81) | 100A028 |

| APSON SR-24-JSB Hose-Connector for Stub Connection 6x9 mm, with integrated blocking function (only for Lacquer Valve 060A070-81) | 100A029 |

| APSON SR-24-SKN Key with pins, for the nut with holes | 100-1785 |

| APSON SR-24-SKR Key with pins, for the Rotor | 100-1786 |

Options: Holder, Adapter, Coupling. Special variants are deliverable in accordance with specifications from the client.

(!) If hot-swap functionality for the valves of the stator is required, please order valves of type ..-81 and adequate connectors with blocking functionality (..YUB resp. ..JSB).